Nenhum produto no carrinho.

(1) Properties

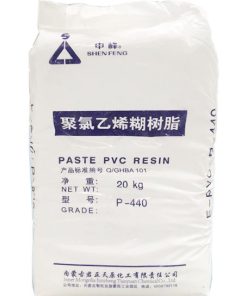

The resin for PVC paste is a homopolymer of vinyl chloride produced by the micro-suspension method. After being mixed with processing aids such as plasticizers, it is formed into a dispersed paste, so it is called paste resin or paste resin. Resin for paste.

(2) Specifications

TPH-31, its degree of polymerization is 1500-1700;

TPM-31, its degree of polymerization is 1230-1430;

TPL-31, its degree of polymerization is 880-1080.

(3) Applications

PVC paste resin is mainly used for processing and coating artificial leather, wallpaper, colored steel plate, foam floor, gloves, slush or spin-casting toys, portraits, artificial melon and fruit samples, plastic flowers, etc. It can also be used to formulate coatings, adhesives, inks and sealing materials. Polyvinyl chloride paste resin has the characteristics of cheap processing equipment, simple and cheap molds, easy foaming, can be made into special shapes, fewer products are processed and heated, and can be produced in small quantities and multiple varieties, and is widely used.

(4) Product packaging and storage

The products are packed in kraft paper bags lined with plastic film bags, polypropylene woven bags or composite bags of kraft paper and polypropylene woven fabrics, with a net mass of (25.0±0.2) kg per bag.

It should be ensured that the packaging of the product is not damaged during normal storage and transportation, and the product is not contaminated or leaked.

(5) Product Standards

The product conforms to the enterprise standard Q/TWPVC 004-2014 “Polyvinyl Chloride Paste Resin” standard.